Last Updated on January 25, 2026

If you need reliable trailer axles, Dexter and Lippert both deliver quality with broad compatibility in spindle sizes and bolt patterns, allowing some parts interchange. Dexter leads in torsion axle ride comfort due to softer rubber compounds. Lippert offers competitive pricing and serviceability.

Their axle capacities and brake options overlap, but Dexter’s made-in-USA disc brakes add a performance edge. Understanding these nuances will help you make an informed choice tailored to your trailer’s needs.

Key Takeaways

- Dexter axles offer superior torsion dampening and smoother rides due to softer rubber compounds compared to Lippert’s harder rubber designs.

- Lippert axles are generally more cost-competitive with frequent promotions, while Dexter products tend to have a modestly higher retail price.

- Both brands share common spindle and bearing sizes, allowing partial interchangeability of hubs, bearings, and brake assemblies if bolt patterns match.

- Dexter axles provide made-in-USA hydraulic disc brake options and are praised for high reliability and minimal failures over decades.

- Lippert axles are known for ease of service and broad availability but have occasional leveling system issues due to overseas sourcing.

A Practical Comparison of Dexter and Lippert Axles

| Feature | Dexter Axles | Lippert Axles |

|---|---|---|

| Ride Quality | Smoother torsion ride with softer rubber | Firmer ride with harder rubber |

| Axle Types | Leaf spring, torsion, air-ride options | Leaf spring and torsion designs |

| Load Capacity Range | Wide range, from light-duty to heavy-duty | Broad coverage, similar capacity options |

| Brake Options | Made-in-USA disc and drum brakes | Drum brakes widely available |

| Build & Reliability | Long-term durability, fewer reported failures | Reliable, but some mixed feedback |

| Pricing | Slightly higher upfront cost | Often more budget-friendly |

| Parts Compatibility | Highly interchangeable components | Good interchangeability |

| Best For | Owners prioritizing ride comfort & longevity | Buyers focused on cost and availability |

Brand History and Market Position

Although Dexter began modestly in 1960 as a supplier of axles for manufactured housing and recreational vehicles, it has evolved into a dominant force in North America’s trailer axle market.

Starting in 1960 with axles for manufactured housing, Dexter has become a leader in North American trailer axles. The company produces over 3 million axles annually and maintains a cumulative installed base exceeding 50 million units. You’ll find Dexter’s growth anchored in a diversified product portfolio that extends beyond light-duty axles to medium-duty axles, brakes, suspension components, and accessories.

Operating within DexKo Global, Dexter leverages a broad manufacturing footprint across 17–18 North American facilities and a strategic acquisition approach to reinforce market reach. Notably, the strategic combination with AL-KO Vehicle Technology in 2016 significantly expanded its product offerings and global presence, forming DexKo Global Inc.

Its leadership continuity is now third-generation, coupled with ISO certifications and rigorous product development, assuring technical excellence. Dexter’s integrated distribution and aftermarket networks further solidify its position as the market leader servicing recreational, marine, commercial, and specialty segments.

This extensive network supports high load capacities and ensures reliable performance across diverse trailer applications.

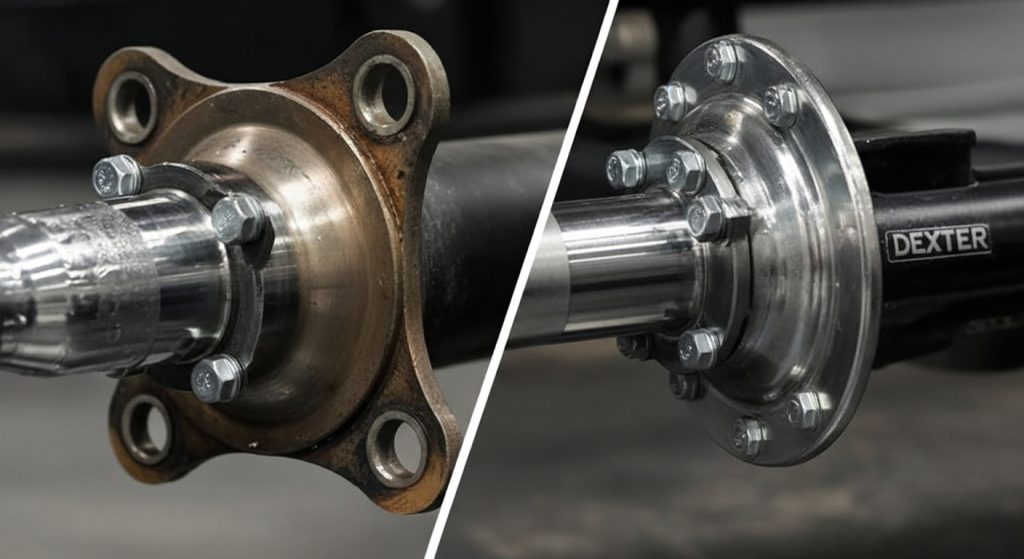

Compatibility and Parts Interchangeability

When you evaluate compatibility between Dexter and Lippert axles, key dimensions like spindle size, bearing fit, and bolt patterns determine parts interchangeability.

Both brands use common spindle/bearing sizes (1.75″, 2.25″), enabling hub and bearing swaps when part numbers and race diameters align. Consider the load capacity of the axle components to ensure they match the trailer’s requirements.

However, wheel bolt patterns (e.g., 6 on 5.5 or 8 on 6.5) must precisely match to safeguard fit. Brake assemblies interchange if mounting bolt patterns and backing plate centerlines coincide, but brake shoe diameter and adjuster types require exact matching.

Spindle length, shoulder placement, and hub flange thickness influence bearing preload and brake clearance, so measure carefully before swapping components. Though seals and grease caps are often compatible, differences in seal lip height or cap depth can cause leaks or preload issues.

Both Dexter and Lippert axles cover a wide range of weight capacities, from 3,500 lb up to 15,000–16,000 lb, ensuring full spectrum coverage for various trailer sizes. Always verify these parameters for safe, effective parts interchange.

Product Specifications and Range

Understanding compatibility between Dexter and Lippert axles sets the stage for evaluating the detailed product specifications and range each brand offers.

Dexter’s axle capacity spans from 2,000 lbs light-duty leaf springs to heavy-duty models rated up to 45,000 lbs. This includes Torflex torsion axles typically rated 6,000–10,000 lbs.

Additionally, Dexter offers axle models with capacities ranging from 1,000 lbs. to 8,000 lbs., covering a broad spectrum of trailer needs. Choosing the correct axle capacity is crucial to ensure safe load support and prevent accidents.

You’ll find multiple ride heights and track widths, supporting single to triple axle layouts. Structurally, tube diameters range from 2.38″ OD on drop axles to reinforced 3.00″ OD with thicker walls for heavy-duty units.

Precision-machined spindles and replaceable bearing journals enhance durability. Brake options cover 7″ to 12-1/4″ drums and disc brakes, with common hub bolt patterns and CSA/FMVSS compliance.

Suspension includes leaf springs, Torflex, and Airflex air-ride assemblies, all with versatile mounting and ride-height configurations. The suspension options include double-eye and slipper spring configurations with underslung or overslung mounting to suit various axle capacities.

Quality, Reliability and User Feedback

Since axle quality critically impacts trailer performance and safety, you’ll want to carefully consider how Dexter and Lippert compare in reliability and user satisfaction.

Dexter leads with torsion axles praised for superior dampening and shock absorption, thanks to softer rubber compounds and heavy-duty components. Lippert matches quality with robust parts but uses harder rubber, resulting in less flexibility. These design choices affect shock absorbency and overall ride comfort.

Consider these points:

- Dexter’s 60+ years of innovation yield top-rated axles with minimal failures.

- Lippert’s overseas sourcing maintains high quality yet shows some leveling system issues.

- Users report smoother rides and better load control with Dexter torsion designs.

- Forums and experts favor Dexter for reliability, while Lippert scores in serviceability.

- The Dexter Easy Flex equalizer includes a grease zerk for maintenance, improving long-term suspension performance compared to factory units that lack this feature.

Pricing, Availability, and Service Considerations

Beyond performance and durability, pricing, availability, and service considerations play a significant role in choosing between Dexter and Lippert axles.

Dexter assemblies typically carry a modestly higher retail price than Lippert’s. However, aggressive Lippert promotions often position it as the cost-competitive option for new trailers. Both brands offer a range of products that maintain compatibility with trailer types, which can simplify selection based on application.

Aftermarket part pricing shows parity due to cross-referenced, interchangeable components. Availability is broad through national distributors, but regional inventory variances and lead times for specialty capacities may influence your choice.

Lippert’s international sourcing can affect supply-chain stability. Service and warranty coverage depend largely on local dealer networks, with faster support where the brand is dominant. Dexter axles feature made in the USA hydraulic disc brake options, which may appeal to buyers valuing domestic manufacturing.

Both brands offer similar routine serviceability, aided by interchangeable parts. Understanding these factors helps you optimize cost-efficiency and maintenance access aligned with your operational needs.

Frequently Asked Questions

Are There Specific Maintenance Tips Unique to Each Brand?

Think of Dexter axles as a finely tuned clock, demanding precise grease types, torque specs, and specific end-play checks for Nev-R-Lube hubs.

You’ve got to follow their detailed repack and brake adjustment schedules to avoid premature wear. Lippert axles, meanwhile, often emphasize suspension alignment and fastener torque sequences to prevent misalignment.

Which Brand Offers Better Customer Support for Commercial Users?

You’ll find Dexter offers better customer support for commercial users. They maintain over 30 company-owned branches nationwide, ensuring in-person assistance and parts availability. Their dedicated online support, detailed warranty processes, and extensive technical resources streamline service.

Lippert lacks comparable centralized support visibility and detailed documentation in this dataset. So, if responsive, accessible support and thorough technical guidance matter to you, Dexter clearly leads in serving commercial customers efficiently.

Can Axle Upgrades Improve Performance on Either Dexter or Lippert Axles?

Yes, axle upgrades can improve performance on both Dexter and Lippert axles.

You’ll gain enhanced ride quality, better load control, and improved braking with options like torsion suspension kits, self-adjusting or disc brakes, and flexible equalizers.

Upgrades reduce bounce, increase durability, and make maintenance easier.

Do Lippert and Dexter Axles Differ in Environmental or Manufacturing Impact?

Think of Dexter’s manufacturing like a precision watchmaker, focusing on domestic production and waste reduction through their Operating System.

You’ll notice Dexter prioritizes durable designs that minimize frame stress and environmental load.

Lippert, meanwhile, acts like a global trader, sourcing parts overseas for quicker turnaround and pricing benefits but increasing supply chain complexity.

Making the Smart Investment After Comparing Dexter & Lippert Axles

When you compare Dexter and Lippert axles, you’ll find both brands offer reliable, well-engineered options that often overlap in parts and specifications. This coincidence simplifies your choice. Whether prioritizing compatibility or pricing, you can trust either for solid performance.

Ultimately, your decision hinges on specific needs and service access. Knowing these brands share strengths lets you confidently select an axle that meets your technical demands without compromise.